When it comes to pumping liquids or gases, diaphragm pumps are a reliable and versatile choice for many businesses. From chemical processing to food and beverage production, these devices are designed to handle a wide range of materials safely and efficiently.

However, with so many options available, selecting the right diaphragm pump for your specific needs can be challenging. This guide aims to make that decision easier by outlining key factors to consider, helping you select the most suitable unit for your requirements.

Understanding The Basics

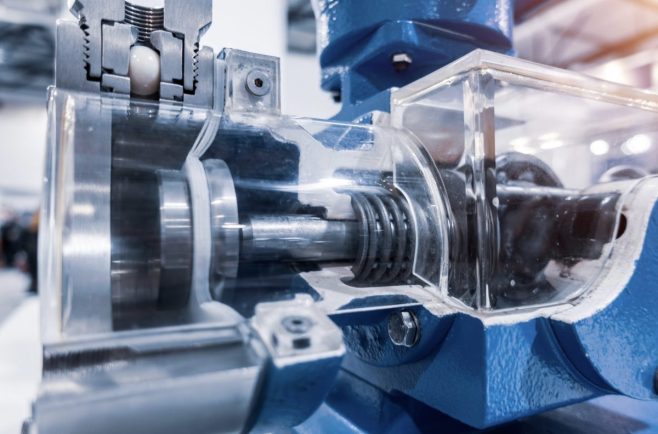

Before discussing the selection process, it’s essential to grasp the fundamental working principles of diaphragm pumps. They operate by using a flexible diaphragm that moves back and forth, creating a vacuum that draws in and discharges the fluid. This design eliminates the need for lubricants, making them ideal for handling corrosive or sensitive materials.

Moreover, the lubricant-free nature of diaphragm pumps, such as those developed by KNF for laboratory applications, ensures their suitability for precise liquid dosing tasks. The absence of moving parts in contact with the fluid minimizes potential contamination risks. Thus, these pumping systems are particularly effective for transferring foods, pharmaceuticals, and other materials requiring high degrees of purity and cleanliness.

Assessing Your Application Needs

Before choosing the right diaphragm pump, thoroughly assess your specific application needs. This will involve understanding various aspects of the fluid you intend to pump and the operational conditions under which the device will function.

- Type Of Fluid: Consider whether you’ll be pumping corrosive chemicals, viscous liquids, or gases. The nature of the fluid greatly influences the type of pump you’ll need. Understanding the fluid’s properties, such as its temperature, viscosity, and potential abrasiveness, is crucial in narrowing down your options.

- Flow Rate: Determine the required flow rate for your application. This refers to how much fluid the pump needs to move within a specific timeframe and is a key factor in selecting the size and type of pump.

- Discharge Pressure: Assess the pressure requirements needed to move the fluid through your system. This includes understanding the height at which the fluid needs to be lifted and the overall length of your piping system.

- Duty Cycle: Decide whether the pump will operate continuously or intermittently. Continuous operations might demand a more robust design compared to one needed for intermittent use.

After evaluating these factors, you’ll be better equipped to make an informed decision about the best diaphragm pump for your application.

Evaluating Pump Construction Materials

Selecting the appropriate construction materials for diaphragm pumps contributes to effective fluid handling and overall performance. The compatibility of materials with the pumped fluids affects the device’s durability and safety:

- Polypropylene or Polyvinylidene Fluoride (PVDF): These materials are ideal for transporting various acids and bases due to their superior chemical resistance.

- Aluminium: Appropriate for certain abrasive liquids, aluminium offers a beneficial combination of durability and lightness.

- Stainless Steel: Suitable for high-temperature liquids or abrasive substances, stainless steel provides exceptional resistance and extended service life.

- Choosing the right material for your diaphragm pump is imperative for efficient operation and avoiding unnecessary maintenance costs.

Considering The Operational Environment

The surrounding conditions where the pump will be used play a significant role in determining the appropriate features and specifications:

- Hazardous Atmospheres: If the pump is destined for environments prone to explosiveness or hazards, opt for units specifically designed for such conditions. These may include special coatings or construction materials for added safety.

- Ambient Conditions: Consider the ambient temperature, humidity, and the presence of dust or debris in the operational area. These factors can affect the pump’s efficiency and durability.

Your diaphragm pump should align with the environmental demands of your operation to prevent premature wear and maintain optimal performance.

Evaluating Pump Accessories and Options

Many diaphragm pump manufacturers typically provide a variety of additional features to improve functionality, safety, and user convenience:

- Pressure Relief Valves: These are essential for preventing over-pressurization, hence ensuring the safety of your system.

- Pulsation Dampeners: These accessories reduce pulsation and fluid turbulence. They can be particularly beneficial for shear-sensitive fluids to prevent material damage.

- Connection Options: Various piping and fitting choices can accommodate different system configurations and fluid types.

Tailor your pump setup with the necessary enhancements to match your operational demands while adhering to safety standards.

Factoring In Maintenance and Support

Proper maintenance is crucial for ensuring the longevity and reliable performance of your diaphragm pump. When selecting one, consider the ease of maintenance, availability of spare parts, and the manufacturer’s support and service offerings.

Pumps with modular designs and easy-to-access components can simplify maintenance tasks, reducing downtime and associated costs. Additionally, partnering with a reputable manufacturer that provides comprehensive support and training can be invaluable in maximizing your unit’s lifespan and minimizing operational disruptions.

Conclusion

Selecting the right diaphragm pump for your business needs is a vital decision that can significantly impact your operations, safety, and bottom line. By carefully considering your requirements and the options available, you’ll be well-equipped to make an informed choice.

Investing in the right diaphragm pump can pay dividends in terms of efficiency, reliability, and long-term cost savings for your business.